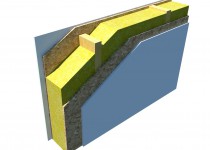

The panel structure may be adjusted according to the wishes of the customer or requirements of the construction regulations of a particular country

The panel structure may be adjusted according to the wishes of the customer or requirements of the construction regulations of a particular country.

The panel structure may be adjusted according to the wishes of the customer or requirements of the construction regulations of a particular country.

The panel structure may be adjusted according to the wishes of the customer or requirements of the construction regulations of a particular country.